Combustion of packed beds of solids - smoldering in carbonaceous porous media and in oil shale

Actions

Partners in the project Action Concertée Incitative "Combustion en milieu poreux" J-F. Thovert, ENSMA Poitiers

The structure of a combustion front propagating in a fixed bed of crushed oil shale : co-current configuration

PhD work of Marcio Martins

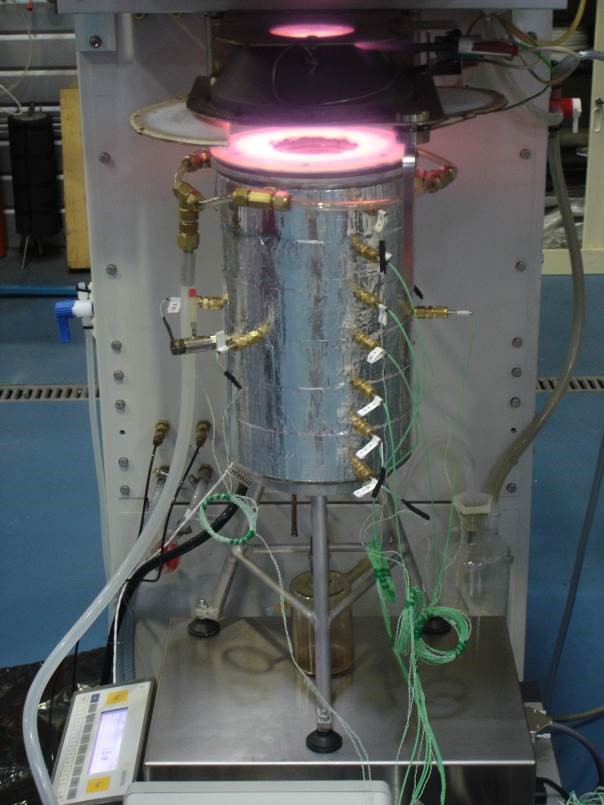

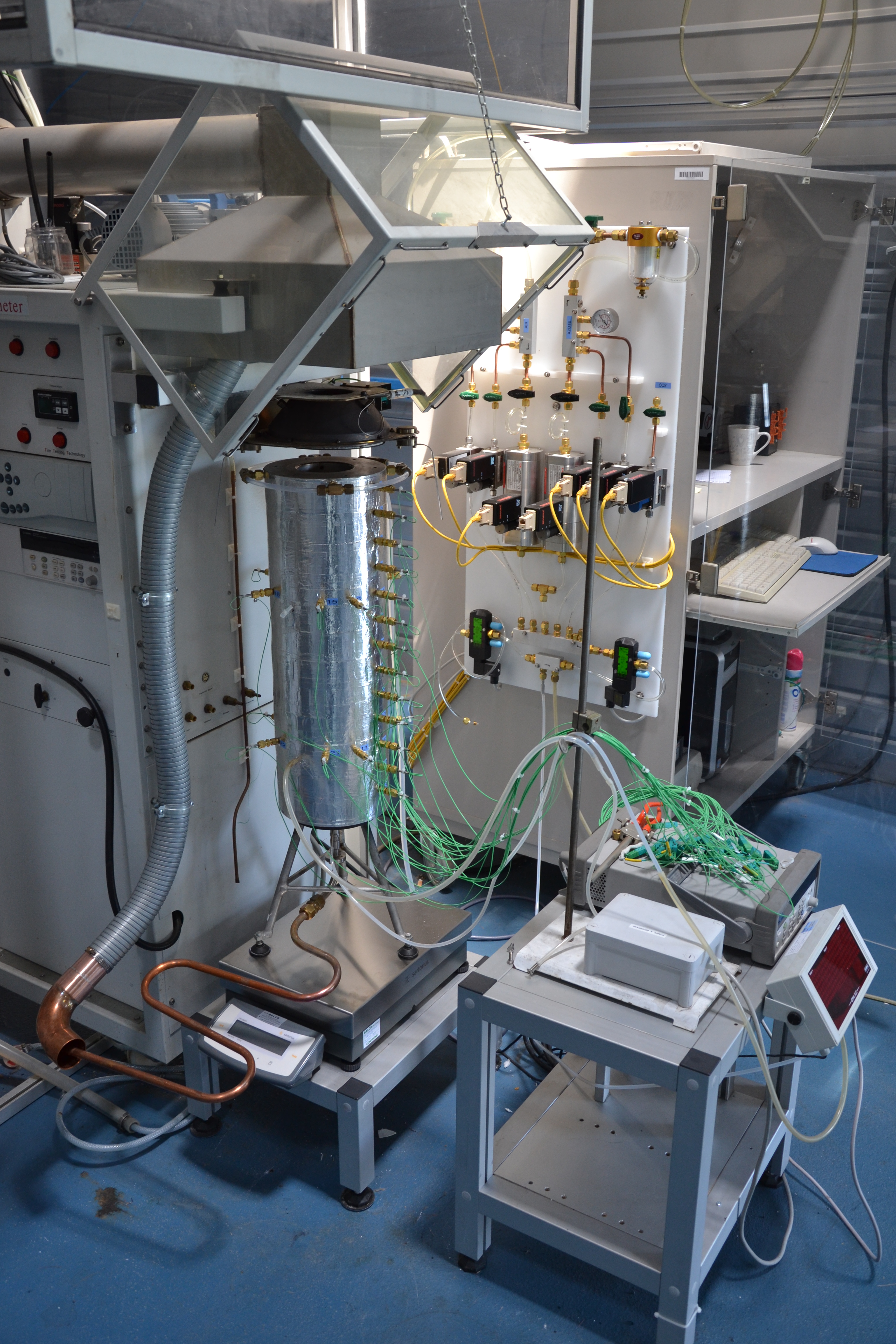

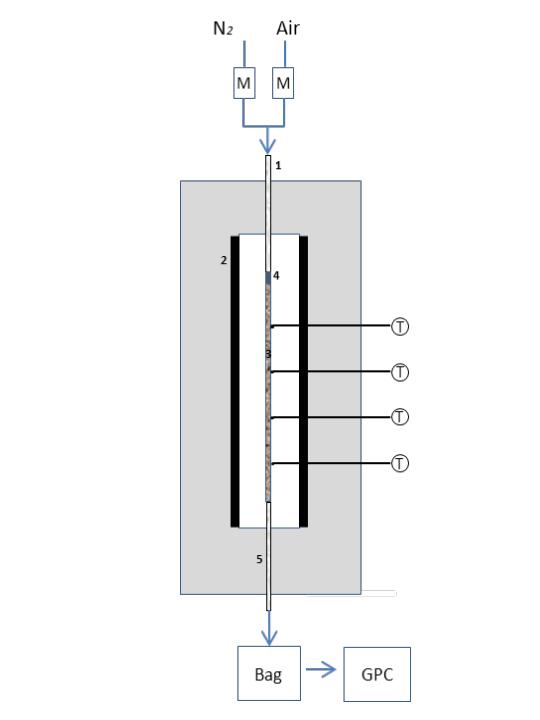

- construction of a combustion cell;

- detailed characterisation of oil shale: chemical composition, proximate and ultimate analysis, thermal properties;

- establishment of a mass balance for the combustion front;

- establishment of the front structure: devolatilization zone, carbon oxidation zone, decarbonation zone;

- 1D numerical modelling of the front propagation.

Institut National Polytechnique de Toulouse, Septembre the 29th 2008

Abstract: The propagation of a combustion front in reactive porous medium involves thermal, chemical and fluid flow mechanisms, with strong couplings. In order to describe the thermal and chemical structure of the combustion front, a new experimental device, finely instrumented, allowing to carry out 1D experiments in co-current combustion was designed and developed. To validate the combustion cell, a porous medium model - a mix of charcoal/sand was used. This fixed bed down flow reactor is equipped with an original system that allows micro sampling gas within the combustion front. For the experiments with the oil shale from Timahdit in Morocco, it was crushed and sieved into particle size at 500-1000 ?m and mixed with sand. The combustion was carried out at air velocity of 0.024 m s-1 at STP. The front propagates at 6.13x10-5 m.s-1 and its temperature peak is 1100 °C. A mass balance was made based on a detailed chemical and physical characterization of the medium, its solid residue after combustion and flue gas. The organic matter is converted into ¼ of fixed carbon - which the oxidation reactions provide the energy to propagate the front - ¼ into pyrolysis gas and ½ into oil. A two temperature numerical model developed by IMFT was validated. Combining experimental and numerical approach made it possible in fine to evaluate the thickness of the different reaction zones: oil shale devolatilization, fixed carbon oxidation and CaCO3 decarbonation. A parametric study varying the air velocity and particle size is finally proposed.

Control of the smoldering front temperature in a carbon- and carbonate-containing porous medium in order to limit CO2 emissions

PhD work of Mohamed Sennoune

- variation of carbonate and fixed carbon contents;

- propagation in the reaction leading and reaction trailing modes;

- use of CO2 enriched gas to feed the front;

- prediction of the front temperature from a global heat balance;

Institut National Polytechnique de Toulouse, November the 8th 2011

Abstract: This PhD thesis focuses on the control of the smoldering front propagating in a porous medium containing fixed carbon and carbonates (CaCO3). The main objective is to reduce the front temperature, in situ (oil recovery or gas production from oil shale) or in process (combustion of semicoke), in order to limit the medium decarbonation and the resulting CO2 emissions. The reactive porous medium retained to realize the laboratory experiments is a crushed (0.5 to 2 mm) and pre-pyrolyed oil shale, called semicoke. The front propagates in co-current. The first technique experimentally tested is the addition to the semicoke of an inert material (sand) and/or a reactive material (CaCO3) to vary the contents of fixed carbon and of CaCO3, independently. We show that the increase of the CaCO3 content enables to reduce the temperature to 800 °C, but not below; this does not allow to avoid decarbonation. Bringing down the fixed carbon content enables to reduce the front temperature, see even to reach extinction. In the lowest temperatures of propagation, the decarbonation is strongly limited. On the other hand, the front slows down because it does not use all of the fed oxygen. The second original technique consists in adding CO2 (20 mol.%) to the oxidizer air. We show that for a hot front, the decarbonated fraction is reduced from 100% down to 70%, and the CO production at fixed carbon oxidation is increased; this leads to increase the LCV of the produced gas. For a cold front, the decarbonation which was 20%, is totally avoided by adding CO2. Finely, experiments are proposed in the "reaction trailing" combustion mode, little known and implemented. This mode has the major interest to avoid the reactions of "Lower Temperature Oxidation" prejudicial for oil or gas yields in in situ process. Stable and repeatable experiments are realized with different oxygen fractions in feeding gas. The front temperature is directly linked to this parameter; the decarbonation is clearly limited in this mode of propagation. Two types of modeling are proposed. A mass and thermal balance based on simple analytical expressions enables to evaluate the front temperature and velocity. A numerical model developed by IMFT is based on convective/diffusive heat and mass transfer equations coupled with the oxidation reactions (into CO and CO2) and CaCO3 decarbonation is proposed. It describes in a very satisfactory way the experiments in the "reaction leading" mode with variation of the medium composition (first technique).

1D modelling of smoldering in a coarbonaceous and carbonates containing non consolidated porous medium

Post-doctoral work of Hossein Fadaei

June 2010 to August 2010.

- 2D numerical modelling of experiments;

- validation by confrontation with experiments.

Solid/Gas Combustion in porous media : multiple scale analysis and heterogeneities analysis

Partners in the CNRS funded project INSICOMB, IMF Toulouse, G. Debenest.

PhD work of Sébastien Balin

Started on November 2011.

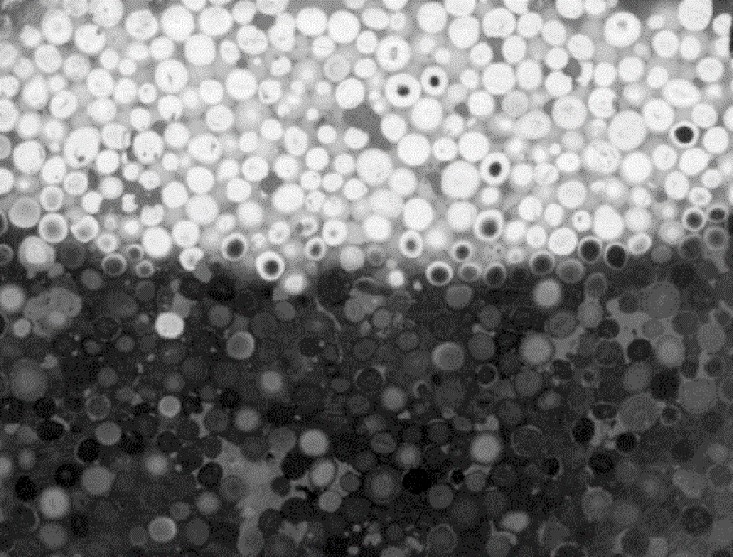

Development of model media from inert porous balls and carbon addition.

Focus on carbon oxidation in fixed bed conditions with forced co-current flow of air. The ratio of CO and of CO2 formed.

Development of a new experiment: the combustion tube. It enables to force the chemical front temperature and to vary the Peclet number.

Study of the capacity of fronts in the reaction trailing mode to cross large banks of inert medium

1D and 2D Darcy scale modelling.

|

|

|

|

|

|

Longitudinal cut of a home made model medium around the front zone after quenching the propagation, cooling and fixing with a resin

Publications

Numerical Simulation of Combustion in Reactive Porous Media

A. Lapene, G.. Debenest, M. Quintard, M. Martins and S. Salvador

International Review of Mechanical Engineering, REME, Vol. 12, Praise Worthy Prize, ISSN 1970 - 8734, September 2008

Co-current combustion of oil shale - Part 1: Characterization of the solid and gaseous products.

M.F. Martins, S. Salvador, J-F. Thovert, G. Debenest

Fuel, Volume 89, Issue 1, January 2010, Pages 144-151

Co-current combustion of oil shale - Part 2: Structure of the Combustion front.

M.F. Martins, S. Salvador, J-F. Thovert, G. Debenest

Fuel, Volume 89, Issue 1, January 2010, Pages 133-143

Application of inverse problem and thermogravimetry to determine the kinetics of oil shale pyrolysis

M. A. B. Zanoni, H. M. Fonseca, M. F. Martins, S. Salvador

High Temperatures-High Pressures -The International Journal of Thermophysical Properties Research, Volume 41, Number 3, 2012.

Reducing CO2 emissions from oil shale semicoke smoldering combustion by varying the carbonate and fixed carbon contents"

M. Sennoune, S. Salvador, M. Quintard

Combustion and Flame , 2011 , vol. 158, n° 11. - p.2272-2282

Impact of a CO2 enriched gas on the decarbonation of CaCO3 and on the oxidation of carbon in the smoldering process of oil shale semicoke

Sennoune M., Salvador, S., Debenest G.

Energy and Fuels, 2012 , vol. 26, n° 1. - p.391-399

Modelling of non-consolidated oil shale semi-coke forward combustion: influence of carbon and calcium carbonate contents

H. Fadaei, M. Sennoune, S. Salvador, A. Lapene, G. Debenest

FUEL, Volume 95, May 2012, p. 197-205

Toward the control of the smoldering front in the reaction trailing mode in oil shale semicoke porous media

M. Sennoune, S. Salvador, M. Quintard

Journal of Energy and Fuels 2012, 26, 3357-3367

New granular model medium to investigate smoldering fronts propagation - Experiments

Baud, Germain; Salvador, Sylvain; Debenest, gérald; Thovert, Jean-François

Energy and Fuels 29 (10), pp.6780-6792, 2015.

Darcy Scale Modeling of Smoldering: Impact of Heat Loss

Victor Pozzobon, Germain Baud, Sylvain Salvador, Gérald Debenest

Combustion Science and Technology 189 (2), pp.340-365, 2017.

Congress

Heat and mass transport in a reactive porous medium: Application to oil shales and heavy oil combustion.

A. Lapene, G. Debenest, M. Quintard, M.F. Martins, S. Salvador

2007 Annual Meeting AIChE, Salt Lake City, Utah (USA), 2007

Thermochemical characterization of a combustion front propagation in reactive porous medium: a new experimental device

Martins M.F., Salvador S., Commandré J-M., Lapène A., Debenest G., Thovert J-F., Commandré J-M.

Eurotherm Seminar N° 81 Reactive Heat Transfer in Porous Media, Ecole des Mines d'Albi, France June 4 - 6, 2007

Numerical simulation of oil shale combustion in a fixed bed: modelling and chemical aspects.

A. Lapene, M.F. Martins, G. Debenest, S. Salvador, M. Quintard

Eurotherm Seminar N° 81 Reactive Heat Transfer in Porous Media, Ecole des Mines d'Albi, France June 4 - 6, 2007

Caractérisation thermochimique de la structure d'un front de combustion en milieu poreux réactif : nouveau dispositif expérimental.

M.F. Martins, S. Salvador, A. Lapene, G. Debenest, J.-F. Thovert, J.-M. Commandré

Congrès SFT 2007, Société Française de Thermique, 29 mai - 1er juin - les Embiez, France

Modeleisation numérique de la combustion en lit fixe de combustibles solides.

A. Lapene, M.F. Martins, G. Debenest

Congrès SFT 2007, Société Française de Thermique, 29 mai - 1er juin - les Embiez, France

Pyrolysis and combustion of oil shale for oil recovery

M. Martinsa, S. Salvadora*, G. Debenest, J-F. Thovert

18th International Symposium on Analytical and Applied Pyrolysis, Canary Islands, Spain. 18-23 may 2008. Oral presentation.

Oil recovery by pyrolysis and complete gasification of oil shale

Márcio F. Martins and Sylvain Salvador

2010 1st Annual World Congress of Well Stimulation & Enhanced Oil Recovery (WSEOR), Abstract and Oral presentation by M. Martins

Mixing of an Oil Shale with inert or reactive media to avoid decarbonation at the passage of the combustion front

M. Sennoune; S. Salvador; G. Debenest; V. Mourzenco

Canadian Unconventional Resources and International Petroleum Conference; 19-21 octobre 2010, Calgary, Canada. Paper and oral presentation

Contrôle de la température d'un front de combustion lors de son passage dans un lit fixe de Schistes Bitumineux.

M. Sennoune et S. Salvador

Congrès français de thermique, Perpignan , 24-27 Mai 2011. Article et Poster.

CO and CO2 formation at carbon smoldering - Combustion tube experiments

Sébastien Balin, Sylvain Salvador, Gérald Debenest, Jean-Francois Thovert

MCS 2015 - 9th Mediterranean Combustion Symposium, Rhodes, Greece, 12 p, June 2015.